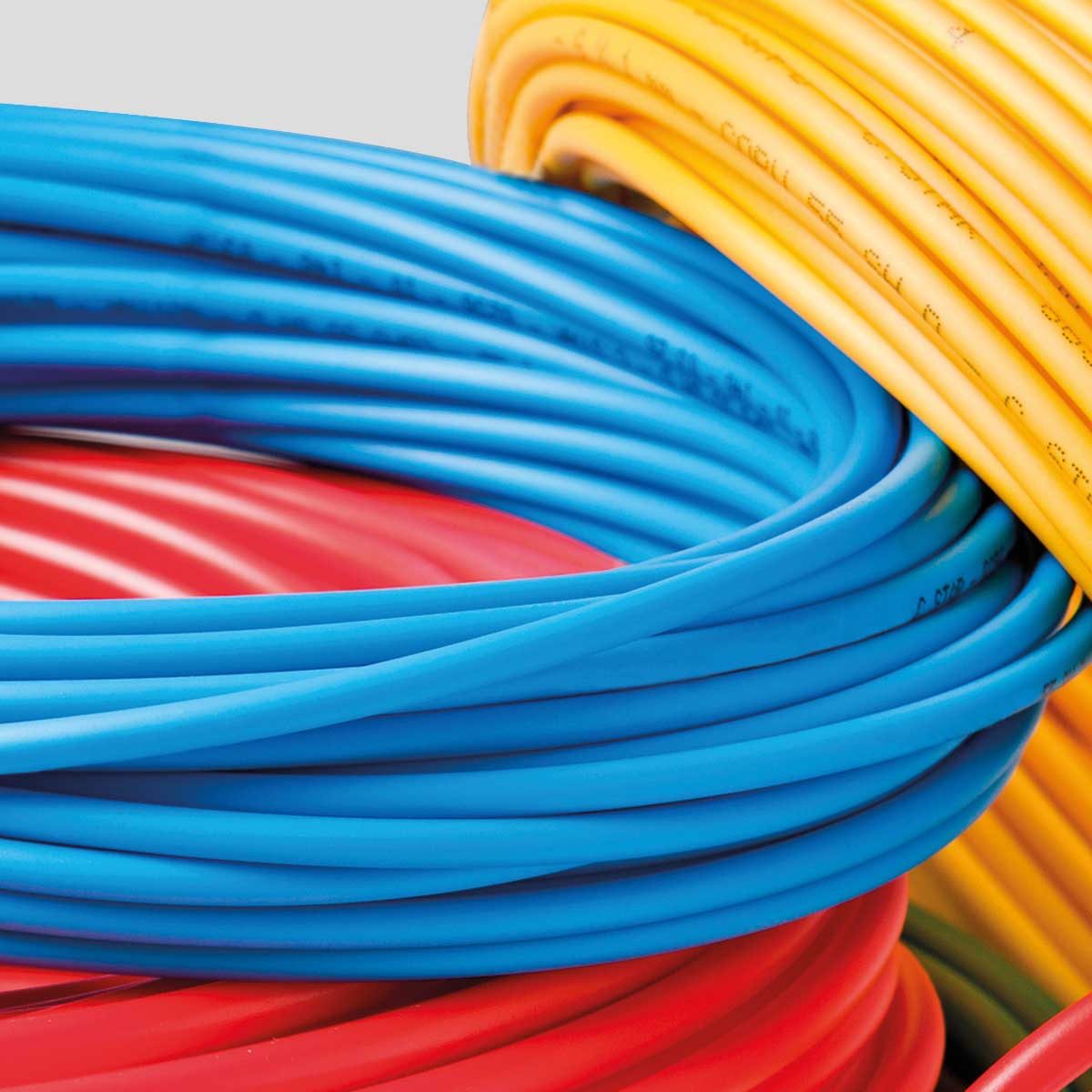

C.BEST tubes are made of Polyamide 12 (PA12), a multipurpose material, derived from Oil.

C.BEST tubes comply with DIN 73378 and DIN 74324 norms.

C.BEST tubes combine excellent mechanical and chemical resistance from -40°C to +130°C.

C.BEST – PA12 HIPHL

C.BEST – PA12 HL

C.Best tubes made of Polyamide 12 are fulfilling the requirements of the standard DIN 73378 / 74324. Rigid Tubes in PA12 HL are generally used for greasing and misting systems thanks

to excellent mechanical and chemical properties.

C.BEST – PA12 PHL

C.BEST flexible tubes made of Polyamide PA12 PHL are recommended for industrial and automotive applications. Tubes in PA12 PHL can be used to safely transfer compressed air and fluids in harsh environments thanks to their remarkable mechanical and chemical properties.

C.PRO – PA 10.12 HL

PA10.12 tubes have been certified TÜV SÜD and fulfillall requirements of ISO 7628/2010. They can easily replace the PA11 and PA12 for the industrial and automotive applications offering the similar chemical and mechanical properties. Tubes in PA10.12 HL are suitable for high pressure applications such as centralized greasing and water misting.

C.PRO – PA 10.12 PHL

PA10.12 tubes have been certified TÜV SÜD and fulfillall requirements of ISO 7628/2010. They can easily replace the PA11 and PA12 for the industrial and automotive applications offering the similar chemical and mechanical properties. Tubes in PA10.12 HL are suitable for high pressure applications such as centralized greasing and water misting.

C.BIO – PA 11 HL

PA11 HL C.BIO tubes are used in both industrial automation and automotive applications and they are made using Polyamide 11, a polymer produced from a renewable source (castor oil). PA11 HL rigid tubes are recommended for their resistance to high pressure.

C.BIO – PA 11 PHL

PA11 PHL C.BIO tubes are used in both industrial automation and automotive applications and they are made using Polyamide 11, a polymer produced from a renewable source (castor oil). These flexible tubes can resist to impact at cold temperatures.

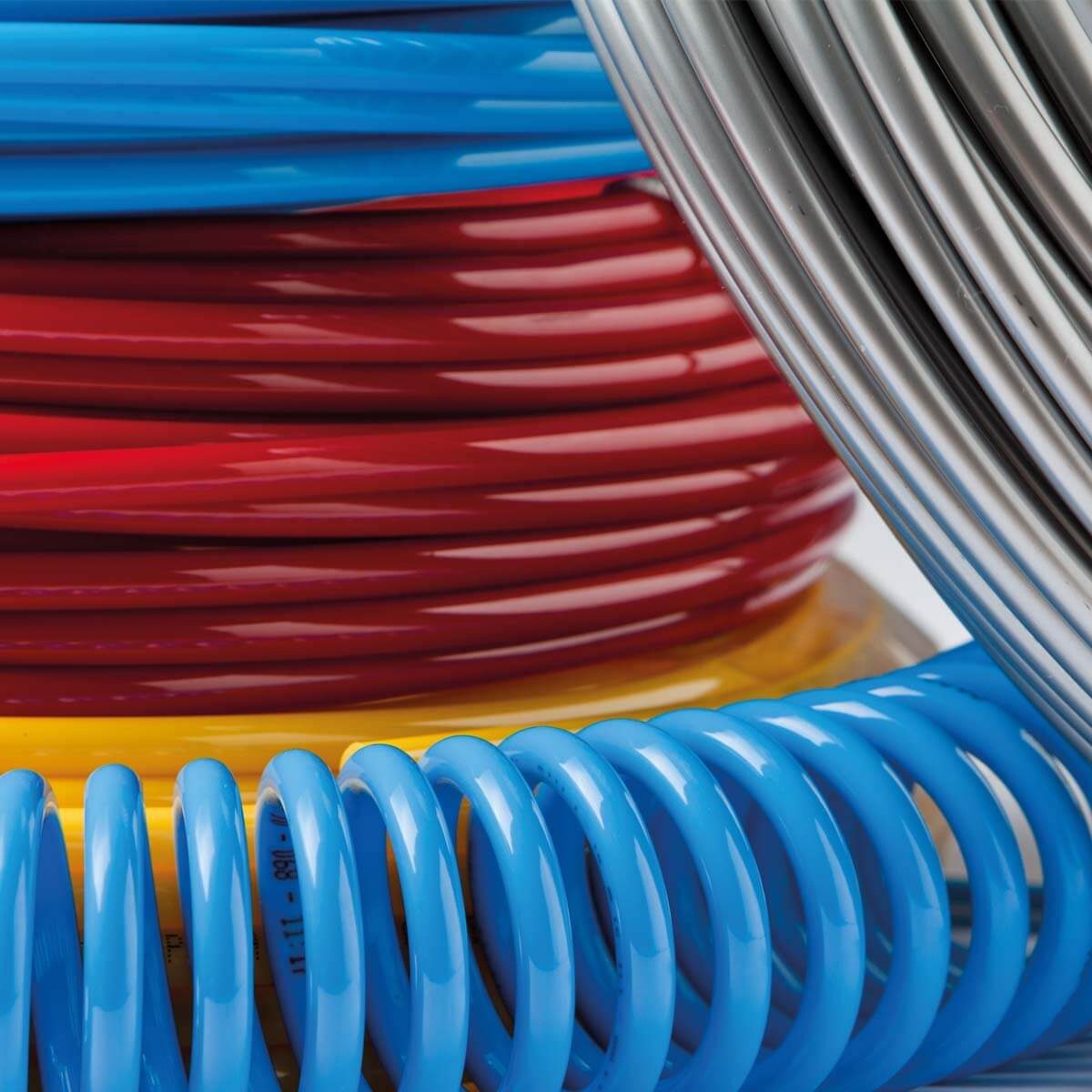

C.STAR

This very innovative tube combines in one product the best properties of polyurethane and Polyamide. C.STAR tubes are made of an exclusive recipe of co-polymers and offer high flexibility, excellent bending radius, good chemical resistance, excellent temperature resistance.

C.ECO

Low density Polyethylene tubes can be used within a restrictive range of temperatures between -40°C and +60°C. C.ECO tubes made in Polyethylene for pneumatic applications are extruded in low-density grade (LD PE).

C.SIX – PA6 HL

C.SIX rigid tubes made of Polyamide PA6 HL are used in pneumatic and industrial high-pressure applications in controlled environments.

C.SIX – PA6 HIHL

Flexible C.SIX tubes made of Polyamide PA6 HIHL are mainly used for common pneumatic applications offering an excellent quality/price ratio.

C.FLEX 95

Flexible C.FLEX 95 tubes are made of polyurethane polyether base shore 95 A. They offer a good resistance to microbiological attack and are suitable for non-drinkable water contact.